Share

SALT LAKE CITY — As he goes about the busy day-to-day work of transforming the Church Office Building Plaza as part of the Salt Lake Temple renovation, Errold Tuley’s noticeable bounce in his step springs from a quiet confidence that the completed project will one day uplift and inspire untold numbers of visitors.

“When this project is finished, it is going to be spectacular,” Tuley, a concrete general foreman for Jacobsen Construction Company, said cheerfully. “The site work planned for this project is just incredible.”

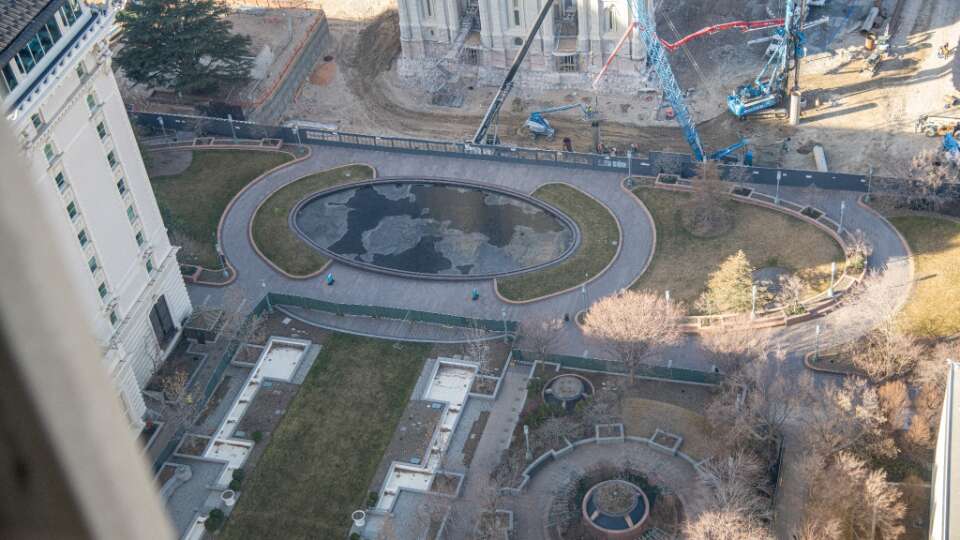

Tuley would know. He is responsible for overseeing all of Jacobsen’s efforts on the Church Office Building Plaza, which is being transformed to include an elliptical array of national flags from all over the world and abundant gardens and green space. Before construction, the plaza included an enormous water fountain feature, but that feature and the plaza concrete had long been leaking, creating potential problems for the parking garage located underneath. In the Spring of 2021, the water fountain, existing landscaping and short concrete walls, risers and benches were removed, and the existing concrete plaza surface was strengthened and re-laminated, to make way for the plaza’s grand new layout.

“The design work, the research and the craftsmanship of this transformation all account for every single little detail on the plaza and the rest of the Temple Square campus,” Tuley said.

Salt Lake Temple roof improvements

As the Salt Lake Temple renovation entered its second year, the spring of 2021 brought with it multiple major advances in the progress of this generationally significant project. In May, construction teams began to reinforce the roof of the temple with new steel trusses designed to better support newly installed mechanical, electrical and plumbing system equipment in the attic and to protect against earthquake activity as part of the building’s overall seismic strengthening. The roof will also be able to more easily handle snow loads in the winter after its reinforcements are complete.

“A good roof structure is so critical for this project,” said Jacobsen Construction Project Manager Josh Fajardo, who is overseeing all work on the roof. “We have all the historic finishes inside the building that we’re trying to preserve. And starting from the top down, that means providing impermeable protection against the natural elements, plus seismic support.”

On a typical project, all trusses would be installed at the same time, but on this project, construction teams did so one at a time so they could rapidly complete each truss installation in a way that protected the sensitive historical interior of the temple as much as possible — with two separate water protection methods put into place in case of rain.

Remarkably, the original temple structure itself included steel trusses as well. Those were removed in conjunction with adding the new ones, and their significant historical architectural features were removed for preservation.

“Looking back and thinking about how the pioneers built this, all the challenges they had, is just amazing. These days, we’re fortunate to have these impressive cranes that make it so much easier to get materials up to and down from the top of the temple,” Fajardo said.

The new building systems located in the attic — comprised of heavier mechanical, electrical and plumbing equipment than was located there in the past — needed to be installed by builders stationed on top of the roof, so that task was completed concurrently with the installation of the new trusses. Attic catwalks were also installed concurrently.

The spires and roof of the temple are also in the process of being directly connected to the entire apparatus of the temple’s new seismic protections. This will be done through inserting steel cable rods into the roof and the spires, with these rods connecting to the new structural steel framework of the building, all the way down to the very foundation of the temple. Horizontally oriented steel cable rods are also being put in, giving the whole top of the temple the optimal architectural tension and sturdiness to withstand heavy earthquake activity — just like the rest of the structure.

Keeping the temple steady while seismic supports change

In the interior of the temple, an enormous and intricate hydraulic jack and steel beam system has been temporarily installed between the fourth and fifth floors. This system ensures the temple stays architecturally stable during the building’s long transition period between the removal of original architectural supports that were once holding up the building and the eventual completion of the permanent structural steel system that will replace those old features.

“Previous structural features that were holding the building up needed to be replaced with more architecturally advanced structural steel, which will help the temple be better prepared for seismic events,” said Jacobsen Construction General Foreman Cody Capson, who oversees the temporary load transfer system.

“In the meantime, until we can put in more of that structural steel, these temporary steel beams provide needed seismic improvements, and make up for the absence of the previous, outdated structural features that were removed.”

The half a dozen or so massive, horizontal steel beams weigh a combined 200,000 pounds. These unwieldy and heavy beams were delivered to the interior of the temple through a complex process that required that each beam to be hoisted by crane through windows on the south side of the temple in three separate segments each. Once inside the temple, each beam was then moved into place by gantry cranes. Finally, each beam was bolted together after its three segments had been moved to the correct location.

The temporary load bearing system is created by connecting the beams to hydraulically operated jacks that can be programmed to prop up the beams with precisely the amount of pressure that is calculated to be optimal for the structural stability of the building. Considering the overall structural composition of the temple, this meant the steel beams, located between the 4th and 5th levels, needed to be fine-tuned to both push down on the 4th level and push up on the 5th level of the temple.

“At the time of installation, the levels of pressure we applied to the beams were brought up in small increments, until we made sure we were supporting all the weight we needed to. To do a successful load transfer with a historic structure all around you, you don’t want to lift the entire thing all at one time. The best and most successful load transfer is a boring one,” Capson said. “So, you accomplish that with small adjustments, small pressure increases, small lifts. And those small increments were also done by increasing the pressure one station at a time in sequence from west to east, and redoing that process over and over, to make sure that we weren’t causing any unnecessary structural strain to the temple.”

The pressure applied by the jacks can be adjusted on an ongoing basis as needed depending on what construction teams see in the measurements gained from continual monitoring of the structural stability of the temple. Sophisticated laser technology and other methods are used to conduct this monitoring. Thus far in the project, no adjustments have been made to the pressure of any of the jacks since the initial installation.

The temporary beams will remain in place until the addition of structural steel to the perimeter walls of the temple — starting at the basement level and moving upward — is sufficient to carry the load once supported by the removed interior walls, columns and arches. As that happens, the jacks carrying the temporary beams can be gradually adjusted to reduce the pressure they are applying to the building, and finally removed in a process just as complex and careful as their original installation.

“As we complete other elements of construction, the jacks will be adjusted as needed so that the pressure they are applying is gradually relieved, as needed, and everything is staying where it needs to be,” Capson said.

The underlying reason the temple structure requires the architectural support of the temporary steel beams in the first place is because they replace the support previously supplied by several walls, columns and arches that have been removed from multiple levels of the temple during the renovation. These beams thus ensure that the architectural method for holding up the temple can be shifted to an improved, modernized structural steel system without any period of structural instability during that transition.

An uncommon project

The exceptionally high stakes of preserving a worldwide religious icon, plus the logistical challenges of piecing together a massive temporary load transfer system in such tight spaces, Capson said, means there are precious few seismic reinforcement efforts anywhere that are comparable to the undertaking made possible at the Salt Lake Temple.

“This temporary load bearing system, with all of its modifications, had to my knowledge never been tried before — this is one of a kind,” he said.

Identifying and using sophisticated and unheard-of solutions to resolve the project’s numerous unique obstacles has been the real thrill of the work, according to Capson.

“Being part of this especially challenging project is a clear once-in-a-lifetime opportunity,” he said. “It’s important to enjoy every second, because you may never get to do a lot of this same stuff ever again. And it requires the contributions of every person involved with the project in order to be successful — no one person could do any part of this project on their own. It takes every bit of our team, every day, doing problem solving.”

Tuley echoed the same feeling about the significance of the project, saying he savors the deep meaning that the freshly renovated Salt Lake Temple and Temple Square campus will hold for worshippers all over the world.

“The chance to take on generational projects like this — mission-critical jobs for organizations that do so much good for people everywhere, like The Church of Jesus Christ of Latter-day Saints does — is my favorite thing about the work we do.”

Photos Credit: Church Newsroom